Chemical And Pharmaceutical Equipment Suppliers

Changshu Longyu Chemical Equipment Co., Ltd. was founded in 1997 and registered as its current name in 2009. The company is located at the west foot of Yushan Mountain in Changshu with beautiful scenery, on the west bank of Shanghu Lake with rippling blue waves, with Shanghai in the east, Wuxi in the west, Zhangjiagang in the north, and Suzhou in the south. The traffic is very convenient. The total area is 14,000 square meters, with more than 50 employees, including technical and management personnel, engineers, etc., with 3 invention patents and 19 utility model patents.

The company has passed the ISO9001 international quality system certification and has a D1.D2 level pressure vessel manufacturing license.

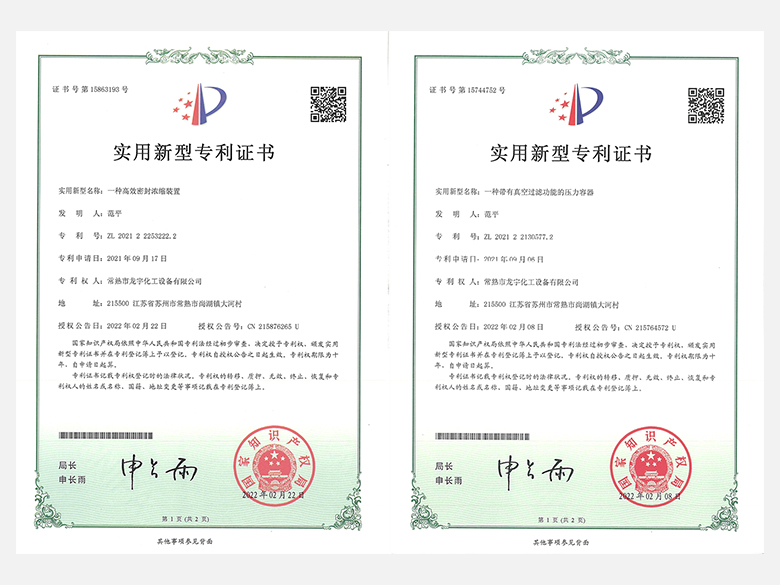

Patents View More

More than 20 years of technical experience

Have Managers and Engineers

Product independent research

3 invention patents, 19 utility model patents

Through quality certification and manufacturing license

Create reliable products for customers

Perfect after sale service

Continuously improve service quality as the pursuit

The company mainly manufactures I and II carbon steel and stainless steel pressure vessels, including reactors, heat exchangers, storage tanks, fermentation equipment, scraped film evaporators, towers, and also produces civilian glycerin equipment and glass-lined equipment products, with a wide range of products. Used in petrochemical, pharmaceutical, food and power industries.

Learn more

The company mainly manufactures I and II carbon steel and stainless steel pressure vessels, including reactors, heat exchangers, storage tanks, fermentation equipment, scraped film evaporators, towers, and also produces civilian glycerin equipment and glass-lined equipment products, with a wide range of products. Used in petrochemical, pharmaceutical, food and power industries.

Learn more

The company mainly manufactures I and II carbon steel and stainless steel pressure vessels, including reactors, heat exchangers, storage tanks, fermentation equipment, scraped film evaporators, towers, and also produces civilian glycerin equipment and glass-lined equipment products, with a wide range of products. Used in petrochemical, pharmaceutical, food and power industries.

Learn more

The company mainly manufactures I and II carbon steel and stainless steel pressure vessels, including reactors, heat exchangers, storage tanks, fermentation equipment, scraped film evaporators, towers, and also produces civilian glycerin equipment and glass-lined equipment products, with a wide range of products. Used in petrochemical, pharmaceutical, food and power industries.

Learn more

The company mainly manufactures I and II carbon steel and stainless steel pressure vessels, including reactors, heat exchangers, storage tanks, fermentation equipment, scraped film evaporators, towers, and also produces civilian glycerin equipment and glass-lined equipment products, with a wide range of products. Used in petrochemical, pharmaceutical, food and power industries.

Learn more

The company mainly manufactures I and II carbon steel and stainless steel pressure vessels, including reactors, heat exchangers, storage tanks, fermentation equipment, scraped film evaporators, towers, and also produces civilian glycerin equipment and glass-lined equipment products, with a wide range of products. Used in petrochemical, pharmaceutical, food and power industries.

Learn moreR&D and Production of Chemical Equipment

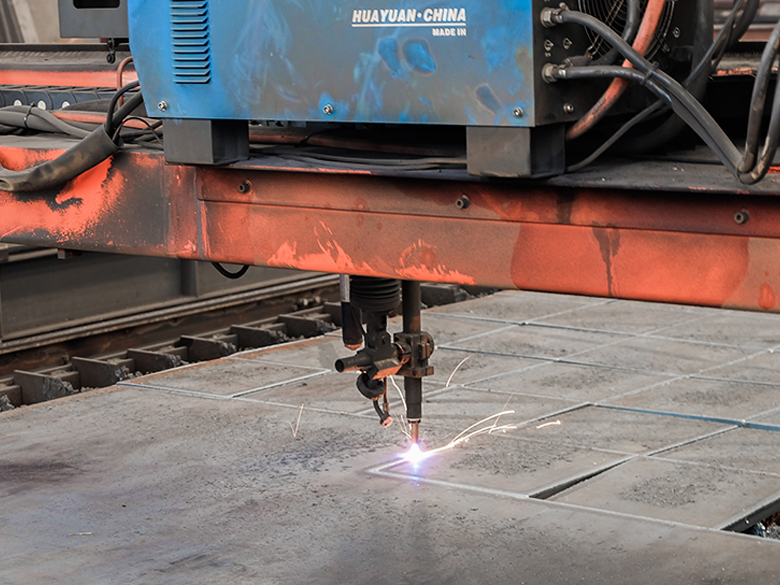

Covering an area of 14,000 square meters, the factory scale integrates from product research and development to finished product sales to ensure product quality.

With technical and management personnel, engineers 50 people.

With different mechanical processing equipment and testing equipment.

Invention Patent

Utility Model Patents

The company has passed the ISO9001 international quality system certification and has a D1.D2 level pressure vessel manufacturing license.

Products include reactors, heat exchangers, storage tanks, fermentation equipment, scraped film evaporators, towers, and also produce civilian glycerin equipment and glass-lined equipment products.

Adhere to technological innovation and promote the sustainable development of the company as the goal.

Products are widely used in petrochemical, pharmaceutical, food and power industries.

Has been sold to Guangdong, Inner Mongolia, Shandong, Hebei, Anhui, Zhejiang, Tianjin, Shanghai and other parts of the province, and has been exported to Thailand and other Southeast Asian countries.

The quality policy is "strengthen process control, produce high-quality products, manage continuous improvement, and ensure customer satisfaction".

Create reliable products for customers and improve service quality as the pursuit.

Strive to become a high-quality supplier of chemical and pharmaceutical equipment.

Be sincere and do things with heart

The polishing treatment core of vertical polishing storage tanks is aimed at the "inner wall in contact with the medium" (some outer walls are polished as needed), reducing surface roughness and optimizing surface conditions through mechanical or chemical processes to achieve the core requirements of high cleanliness, easy cleaning, and corrosion prevention. It is a key process to ensure that the

The carbon steel spiral plate heat exchanger is an efficient heat exchange equipment designed based on a "spiral flow channel". Its structural characteristics revolve around "strengthening heat transfer, optimizing flow field, and adapting to carbon steel material characteristics". The core can be analyzed from four dimensions: core components, flow channel design, sealing structure, and support m

Vertical stainless steel storage tanks are widely used in multiple industries with strict requirements for storage medium purity, safety, and stability due to their core advantages such as corrosion resistance, good sealing, high space utilization, and easy cleaning and maintenance. Specific industries and application scenarios are as follows:

The coil type reactor is a core equipment used in industrial production to achieve chemical reactions. Its core feature is the installation of a "coil" structure inside or outside the reactor body, which controls the reaction temperature correctly through heat exchange between the coil and the materials inside the reactor, while providing a stable space environment for the reaction to efficiently

The application of deodorization towers (whose core function is to remove odorous substances and harmful components from gases through adsorption, absorption, catalysis, etc.) in the energy industry is essentially to adapt to the "environmental compliance" and "safe operation" requirements of the entire energy production, processing, storage and transportation chain - various links in the energy i

The jacketed reactor is widely used in the core process of drug production in the pharmaceutical industry due to its ability to control temperature (heating/cooling) through the jacketed chamber, good sealing, and strong material adaptability. It is particularly suitable for reaction scenarios that require strict temperature control and a sealed environment. The specific applications are as follow